Grain Size 晶粒大小分析 選配模組

| Image-Pro 影像分析軟體 | MA-Pro 金相分析軟體 | 金相材料分析應用介紹 | 金相分析相關國際標準規範 |

應用介紹

INTRODUCTION >> Grain Size | MA-Pro

業界所使用的金屬材料種類繁多,廣泛應用工業、建築、電機、航太、汽車、半導體、電子電路等產業,通常依產品設計所需用途、目的、加工要求等需求來選擇適當的金屬材料進行加工製造。金屬材料的金相組織是由許多結晶粒所構成,結晶粒與結晶粒之間的邊界,亦稱晶界,在金相分析中,晶粒度分析是業界比較常見的試驗方法,也是評估金屬材料性能的重要指標,金屬晶粒尺寸(或晶粒度)對其在室溫及高溫下的機械性質、耐腐蝕性及加工性能有決定性的影響。

晶粒大小(Grain Size)的控制對於許多材料之加工製程的品質管控至關重要,晶粒大小、尺寸與分佈的均勻性會直接影響加工零件的強度和耐用性,晶粒減小通常會提高材料的強度,因晶界可以阻止位錯的移動,然而過小的晶粒可能導致材料的韌性下降,故金屬材料的加工需要在強度和韌性之間取得平衡。若要將金屬材料的晶粒尺寸進行細化,熱處理是最重要的處理方法,熱處理後結晶粒將視其原子的成長排列成特定圖案,形成不同於處理前的結晶晶界。隨著結晶粒粒度(結晶粒度)改變,機械性質也會改變。因此不論進料檢驗或出貨檢驗都需要對金屬材料的晶粒結構有嚴格的品質管控,透過高解析度顯微鏡進行晶粒大小觀察,確保加工材料的機械性質符合製程要求參數,MA-Pro金相分析軟體提供Grain Size晶粒大小分析功能,符合業界常用標準規範,可將晶粒大小準確量化,確保材料符合設計要求,並提高產品的可靠性。

業界常見的晶粒大小分析參考國際標準規範有 ASTM E112 (美國)、ISO 643(全球)、JIS G 0551 (日本)、JIS G 0552 (日本)、GOST 5639 (俄羅斯)、GB/T 6394 (中國) 和 DIN 50601 (德國) 等。雖然國際標準規範種類繁多,其中 ASTM E112 Standard Test Methods for Determining Average Grain Size(平均晶粒度的標準檢測方法)是業界較為採用的標準規範。

以 ASTM E112 為例,規範提供測定平均晶粒度的方法如下:

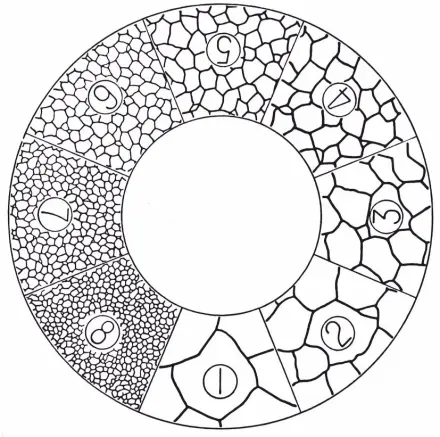

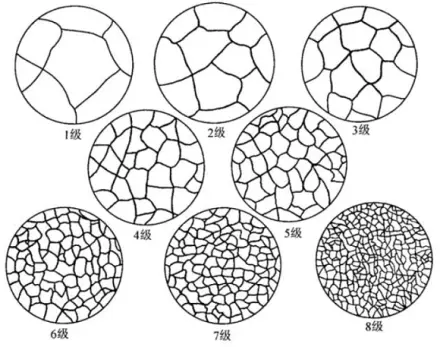

比較法(Comparison Method):

以金相顯微鏡使用固定的光學放大倍率,透過目視方式觀察金相組織與「晶粒度標準圖」比較,或是在目鏡上安裝晶粒尺寸刻劃片,推定結晶粒度的晶粒號數,以比較法進行晶粒度評估,人為主觀因素一般存在一定的偏差( ±0.5 級),評估結果在統計上的重覆性與再現性通常為 ±1 級。

晶粒度標準圖

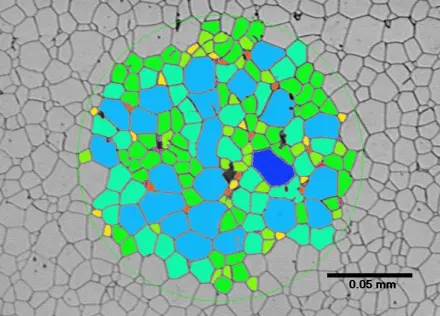

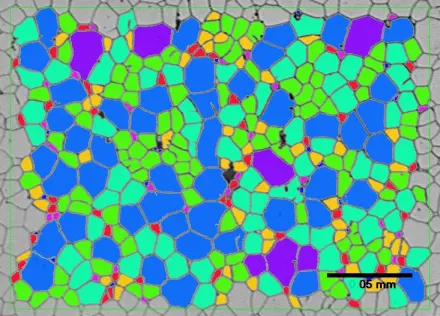

面積法(Planimetric Method):

面積法是計算已知面積內晶粒個數,利用單位面積內晶粒的個數來推定晶粒度等級數,測定的偏差較小,精確度約在 ±0.25 級 ~ ±0.5 級左右 ,評估結果的重覆性與再現性小於 ±0.5 級,但面積法的晶粒度關鍵在於晶粒組織中的晶界必須能夠明顯劃分晶粒進行計數。

截點法(Intercept Method, 又稱截距法):

截點數是計算已知長度的試驗線段或網格,與晶界相交的截點數量,計算出平均截距長並套公式求出晶粒號數,透過影像分析技術準確取得晶粒號數的量化結果,其統計結果可達到 ±0.25 級的精確度,重覆性與再現性小於 ±0.5 級。

關鍵字:晶粒大小 晶粒尺寸 晶粒號數 晶粒級數 晶粒度 晶粒大小分佈 Grain Size Grain Number Grain Size Distribution

分析功能

ANALYSIS FEATURES >> Grain Size | MA-Pro

面積法

Planimetric Method

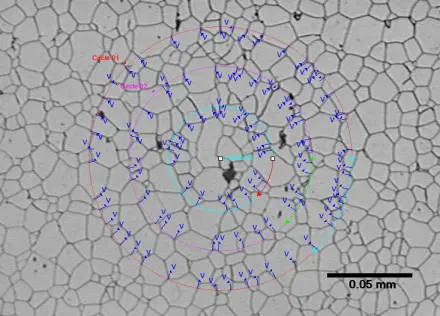

Circular Planimetric

Rectangle Planimetric

截距法

Intercept Method

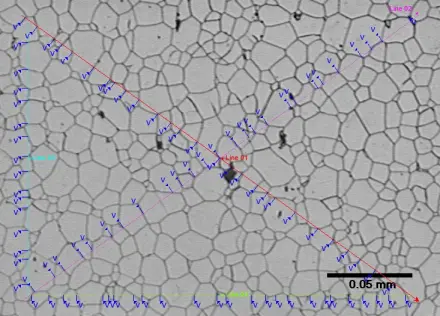

Circular Intercept

Intersect Intercept

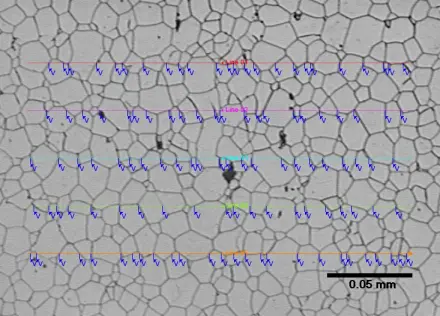

Horizontal Intercept

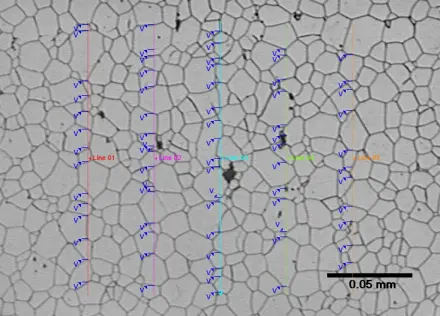

Vertical Intercept

Grain Size 晶粒大小分析功能符合 ASTM E 112、E1382、IS 4748 等國際標準,適用金屬與非金屬材料的晶粒度量測,可用於鋼鐵、鋁合金、鈦合金、多晶矽太陽能板等金屬材料的晶粒大小、晶粒尺寸與晶粒分佈等材料特性評估與品質控制。截距法(Intercept Method)提供多種測試量測線段(Test Pattern),如圓形(Circular Intercept Pattern)、對角線(Intersect Intercept Pattern)、水平線(Horizontal Intercept Pattern)、垂直線(Vertical Intercept Pattern)等方法,並能自動偵測晶界(Grain Boundary),精準計算晶粒號數 (Grain Number),面積法(Planimetric Method)亦可依晶粒號數與晶粒數量製作晶粒分佈 (Grain Size Distribution)圖表。

同時,支援自訂量測區域或範圍,讓使用者可針對特定區域進行分析,提高測試的靈活性與準確度。透過快速量測、自動統計,系統可大幅減少分析時間,並一鍵匯出至 Excel 報表,讓生產與品管流程更加高效。Grain Size 分析系統是材料科學、金相分析、品質檢驗等領域的理想選擇!

Grain Size 晶粒大小分析功能介面

Grain Size Analysis Function & User Interface

操作界面語系支援英文、繁體中文和簡體中文。

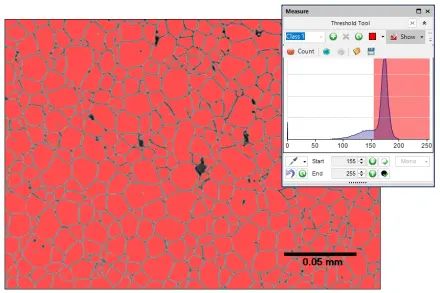

面積法提供晶粒智慧選取工具

Smart Threshold Tool Selects Grains Based on Planimetric Method

提供聰明的灰階選取工具,自動偵測調整灰階閥值,一鍵找出白色肥粒鐵粒狀組織或黑色波來鐵帶狀組織,亦可手動調整灰階選取範圍。

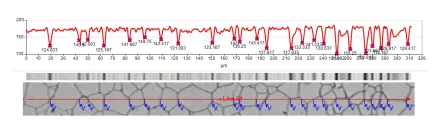

截距法提供多種測試線段

Intercept Method Provides A Variety of Test Pattern for Quickly Measure the Average Intercept length.

截距法提供圓形、對角線、水平線、重直線多種測試量測線段,可自動偵測晶界截點位置,快速的量測並計算出平均截徑長

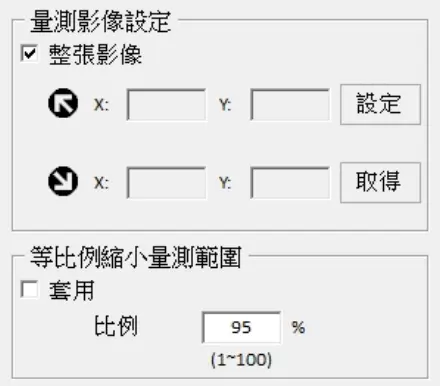

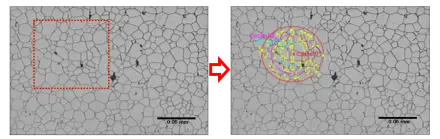

可自訂量測範圍

Customizable measuring range

可依需求定義在影像上需要量測區域或範圍,精準量測所需範圍內的晶粒號數。

快速操作、自動統計

Quick Measurement and Automatic Statistics Then One-Click Export Grain Size Report

快速量測、自動統計、一鍵匯出報表,減少分析時間並提升生產量。量測結果可匯出至Excel報表。

銷售實蹟

OUR CUSTOMERS >> Grain Size | MA-Pro

(實際成交客戶名單持續增加中,若不願公布公司名稱,請來信告知)

金相工業相關:力興緞壓、宏國金屬、傑生工業、速聯、智勝科技、中油、光洋應用材料、嘉冠、富城金屬、昇益工業、力揚、允強、名佳利、奇美實業、國瑞汽車、巧新工業、林吉金屬、承鴻國際、光陽機車、朝新金屬、台灣電力公司、祐群工業、怡聚發條、八合豐、環球檢驗科技。

學術研究單位:中山科學研究院、漢翔、交通大學、中華科技大學、建國科技大學、勤益科技大學、高苑科技大學、義守大學、新竹標檢局、空軍三指部、軍備局、SGS、金屬中心。

如果您對 金相分析軟體 有興趣,歡迎隨時來電洽詢,我們有專業的技術團隊可以提供您滿意的軟體客製化服務。